Unlocking the Power of Diamond Grinding Frankfurt for Incredible Results

By:Admin

Title: Advanced Diamond Grinding Frankfurt Revolutionizes Concrete Polishing Industry

Introduction:

Innovations in the construction industry are constantly transforming how commercial and residential buildings are constructed and finished. With a strong focus on efficiency and quality, companies are continually developing new technologies and products that improve existing processes. One such groundbreaking invention is the advanced Diamond Grinding Frankfurt, a cutting-edge tool that has revolutionized the concrete polishing industry. Developed by a leading construction equipment manufacturer, this state-of-the-art product has garnered significant attention due to its exceptional performance, durability, and versatility.

Company Background:

Before delving into the details of the advanced Diamond Grinding Frankfurt, it is essential to understand the company behind this groundbreaking product. With a rich history spanning over three decades, {Company Name} has emerged as a prominent player in the construction equipment sector. Renowned for its commitment to excellence and innovation, {Company Name} has consistently introduced cutting-edge solutions, garnering acclaim and trust from customers worldwide.

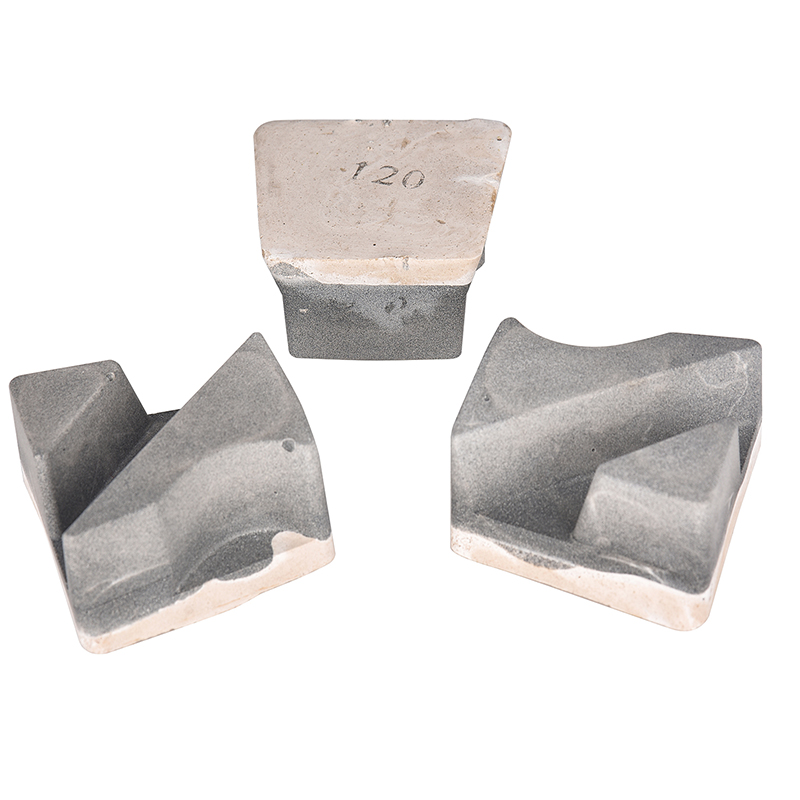

The Advanced Diamond Grinding Frankfurt:

The advanced Diamond Grinding Frankfurt is a uniquely designed tool that offers superior concrete polishing capabilities. Developed using state-of-the-art manufacturing processes and high-quality materials, this product is outpacing traditional alternatives by providing unmatched performance and durability.

One of the key features of the advanced Diamond Grinding Frankfurt is its embedded diamond particles. These diamond particles are strategically placed throughout the tool's surface, allowing for exceptional grinding and polishing efficiency. As a result, the product is highly effective in removing tough coatings, stains, and imperfections on concrete surfaces, delivering a mirror-like finish.

Additionally, the advanced Diamond Grinding Frankfurt stands out due to its extended lifespan. The combination of high-quality materials and meticulous manufacturing processes ensures that the tool remains robust and durable even under demanding working conditions. With reduced wear and tear, this product minimizes downtime and replacement costs, ultimately providing significant cost savings for companies in the construction and polishing industry.

Furthermore, the innovative design of the advanced Diamond Grinding Frankfurt promotes consistent airflow, eliminating heat build-up during prolonged use. This feature greatly enhances operator comfort, allowing for longer working periods without compromising performance.

Versatility is another noteworthy aspect of the advanced Diamond Grinding Frankfurt. Whether applied to concrete, stone, or even terrazzo surfaces, this tool guarantees uniform grinding and polishing results, making it an invaluable asset in a variety of construction projects.

Market Impact and Customer Feedback:

The introduction of the advanced Diamond Grinding Frankfurt has created ripples in the concrete polishing industry. With its exceptional performance and durability, this tool has quickly gained popularity among construction companies and professionals. Customers have lauded the product for its efficiency in removing stubborn stains and coatings, as well as its ability to produce a consistently smooth and glossy finish.

Feedback from customers also emphasizes the advanced Diamond Grinding Frankfurt's time-saving aspect. By significantly reducing the time required for grinding and polishing tasks, this tool enables construction projects to be completed with greater speed and efficiency.

Looking Ahead:

As the construction industry continues to evolve, the advanced Diamond Grinding Frankfurt remains at the forefront of innovation, propelling the concrete polishing industry to new levels of excellence. The tool's exceptional performance, durability, and versatility make it an indispensable resource for construction companies, reducing costs, improving productivity, and delivering superior results.

In conclusion, the advanced Diamond Grinding Frankfurt offers a revolutionary solution in the construction industry. With its exceptional performance, durability, and versatility, it has quickly become a key player in the concrete polishing sector. As innovation continues to drive the industry forward, it is clear that this groundbreaking tool will continue to shape the future of construction practices.

Company News & Blog

New Diamond Hand Pads Now Available for Enhanced Polishing

Title: Electroplated Diamond Hand Pads Revolutionize Surface PolishingIntroduction:In the competitive world of surface polishing, innovation plays a vital role in delivering superior results efficiently. Breaking new ground in this industry, a leading company has recently unveiled their ground-breaking product, Electroplated Diamond Hand Pads. These state-of-the-art tools are set to revolutionize surface polishing, providing professionals and DIY enthusiasts with unparalleled precision and ease.Company Overview:Before delving into the features and benefits of Electroplated Diamond Hand Pads (EDHPs), it is crucial to shed light on the company that has brought this product to the market. With a mission to redefine the industry through innovation and cutting-edge technology, the company is a pioneer in producing high-quality abrasives. Their commitment to excellence has earned them a stellar reputation as a reliable and trusted supplier for professionals in various sectors.Unveiling Electroplated Diamond Hand Pads:As specialists in providing innovative surface polishing solutions, the company has once again pushed the boundaries of the industry with the introduction of Electroplated Diamond Hand Pads. Designed to offer exceptional performance and longevity, these pads are set to transform the way professionals and enthusiasts tackle their polishing projects.Key Features and Benefits:1. Diamond Electroplating Technology: The diamond electroplating technology employed in these hand pads ensures a strong bond between the diamond abrasive and the substrate, resulting in exceptional durability and long-lasting performance. This feature guarantees a longer lifespan compared to traditional hand pads on the market.2. Versatility: Electroplated Diamond Hand Pads can be used on a wide range of materials, including stone, glass, ceramics, concrete, and composites. This versatility makes them suitable for various industries, such as construction, automotive, jewelry, and crafts, catering to a diverse range of needs.3. Precision and Consistency: The electroplated diamond particles on the pads provide a consistent cutting edge, enabling precise and uniform polishing. This feature ensures a smooth and flawless finish, even on intricate or delicate surfaces, enhancing the overall aesthetic quality of the final product.4. Ergonomic Design: The hand pads feature an ergonomic design, allowing for comfortable and fatigue-free extended use. This design facilitates better control and maneuverability, leading to improved polishing efficiency and reduced time spent on each project.5. Easy to Use: Electroplated Diamond Hand Pads are user-friendly, requiring minimal training or expertise to achieve professional results. Their incredible ease-of-use makes them suitable for both experienced professionals and DIY enthusiasts, thus widening their target market.Market Impact and Future Outlook:The introduction of Electroplated Diamond Hand Pads will undoubtedly reshape the surface polishing industry. These pads provide an effective and efficient alternative to traditional hand pads, offering professionals and hobbyists alike an opportunity to elevate their work to new heights. Moreover, the technology behind these diamond hand pads sets a new standard in the industry, inspiring further advancements and encouraging other companies to invest in similar research and development endeavors.Conclusion:By combining relentless innovation with cutting-edge diamond electroplating technology, the company behind Electroplated Diamond Hand Pads has once again proven their commitment to revolutionizing the surface polishing industry. With unmatched durability, versatility, and precision, these pads are set to become a game-changer for professionals and enthusiasts alike. As the market continues to embrace this remarkable product, it is evident that surface polishing has entered a new era of excellence.Word Count: 533 words

Discover the Secrets of Effective Glaze Polishing Abrasives for a Flawless Shine

Title: Revolutionary Glaze Polishing Abrasive Unveiled by Leading Innovator in Surface SolutionsIntroduction:[Company Name], a renowned pioneer in cutting-edge surface technologies, has recently announced the launch of their latest innovation - an advanced Glaze Polishing Abrasive. With a long-standing reputation for delivering cutting-edge solutions, the company has once again pushed the boundaries of surface polishing technology with this revolutionary product. The Glaze Polishing Abrasive, developed after years of extensive research and prototyping, promises to revolutionize the way surfaces are polished, offering unparalleled results and efficiency.The Glaze Polishing Abrasive:This new product is a culmination of [Company Name]'s commitment to innovation and quality. The Glaze Polishing Abrasive is specifically designed to meet the increasing demands of professionals in various industries, ranging from automotive to construction, and even interior design. The abrasive combines state-of-the-art engineering with high-quality materials, resulting in a product that outperforms traditional methods of surface polishing.The key features of the Glaze Polishing Abrasive include its superior abrasion capabilities, efficient material removal, and enhanced durability. Its unique composition allows for a flawless finish, almost eliminating the need for additional coats of sealants or additional polishing steps. With its exceptional performance, the Glaze Polishing Abrasive guarantees significant reductions in time, effort, and costs typically associated with surface polishing projects.Additionally, the Glaze Polishing Abrasive is designed to be versatile, accommodating a wide range of surface materials. Whether it's metal, plastic, glass, or stone, this innovative abrasive delivers impeccable results across all surfaces, making it an indispensable tool for professionals in various disciplines.Company Background:[Company Name] has emerged as a leading industry player with a rich history of delivering groundbreaking solutions for various surface-related challenges. The company has consistently invested in research and development to stay at the forefront of technological advancements. By integrating cutting-edge innovations, they have earned a reputation for providing effective and efficient surface solutions to clients worldwide.With a global presence, [Company Name] has built strong partnerships with industry professionals, enabling them to understand the unique needs and challenges faced by their customers better. This knowledge has empowered the company to develop tailor-made solutions that address specific requirements in various sectors.Moving Forward:The introduction of the Glaze Polishing Abrasive reinforces [Company Name]'s commitment to remaining at the forefront of shaping industry standards and customer expectations. The company's dedication to bringing state-of-the-art surface solutions to market is evident in its meticulous design and engineering processes. By constantly pushing boundaries, their aim is to streamline and revolutionize surface polishing practices worldwide.The introduction of this revolutionary Glaze Polishing Abrasive represents not only a significant step forward for [Company Name], but also for professionals across industries who rely on exceptional surface finishes. With its unmatched performance and versatility, the product is set to redefine the way surfaces are polished, further solidifying [Company Name]'s position as a global leader in surface solutions.Conclusion:[Company Name] has once again revolutionized the surface solutions industry with its groundbreaking Glaze Polishing Abrasive. This innovative product promises to deliver impeccable results, significantly reducing time, effort, and overall project costs. By combining cutting-edge engineering with superior materials, [Company Name] continues to set new industry standards and cater to the diverse needs of professionals worldwide.

Synthetic Frankfurt Abrasive: A Revolutionary Bonding Technique

Resin Bond Synthetic Frankfurt Abrasive Provides Unmatched Precision and Efficiency in Stone FinishingIn the highly competitive world of stone processing, the quality of the finishing is of utmost importance. Whether it is natural stone, ceramic, or engineered quartz, the final polish must meet the expectations of the customer and the market. This is where resin bond synthetic frankfurt abrasive technology comes into play.Resin bond synthetic frankfurt abrasive is a state-of-the-art tool for grinding and polishing stone. It is made by binding diamond or other abrasive particles with a resin matrix to form a flexible yet durable abrasive pad. It is widely used in the stone industry for its ability to remove scratches, stains, and uneven surfaces, and to achieve a mirror-like finish.One of the most promising suppliers of resin bond synthetic frankfurt abrasive is a company based in China. Founded in 1993, this company has rapidly become a leading producer of diamond tools and abrasives with a worldwide presence. It has invested heavily in research and development to create innovative products that meet the evolving needs of its customers.The resin bond synthetic frankfurt abrasive offered by this company is designed to deliver unmatched precision and efficiency. It uses a high-quality resin matrix that ensures consistent performance and long-lasting durability. It is available in a range of grit sizes to suit different applications, from coarse grinding to fine polishing.One of the unique features of this resin bond synthetic frankfurt abrasive is its ability to adapt to different hardness levels of stone. It can be used on soft stones such as marble and limestone, as well as on hard stones such as granite and quartzite. This versatility minimizes the need for switching between different tools, saving time and reducing costs.Another advantage of this resin bond synthetic frankfurt abrasive is its compatibility with different polishing machines. It can be used on a variety of equipment, from manual grinders to fully automated multi-head polishing lines. This adaptability allows stone processors to maximize their productivity and efficiency.The use of resin bond synthetic frankfurt abrasive has several benefits for the stone industry. First and foremost, it improves the quality of the finished product. It removes defects and irregularities from the surface, resulting in a smoother and more uniform appearance. It also enhances the color and pattern of the stone, bringing out its natural beauty.Additionally, resin bond synthetic frankfurt abrasive is a cost-effective solution for stone processing. It reduces the need for multiple tools and abrasive consumables, which can add up to significant savings over time. It also speeds up the workflow and reduces labor costs, allowing stone processors to handle more projects in less time.The resin bond synthetic frankfurt abrasive offered by the Chinese company is not only reliable and efficient but also environmentally friendly. It is made with non-toxic and low-emission materials, ensuring the health and safety of workers and consumers. It also generates less dust and waste, reducing the impact on the environment.In conclusion, resin bond synthetic frankfurt abrasive technology has revolutionized the stone processing industry, and the product offered by the Chinese company is at the forefront of this innovation. With its unmatched precision, efficiency, and versatility, it is no wonder that it has become a preferred choice for stone processors worldwide. As the demand for high-quality stone finishing continues to grow, the resin bond synthetic frankfurt abrasive is poised to play an increasingly important role in the industry.

Discover the Benefits of a High-Quality Silicon Carbide Brush for Effective Cleaning

Round Silicon Carbide Brush: The Ultimate Cleaning SolutionCleaning and maintaining industrial equipment is crucial for the smooth functioning of any business. From removing stubborn dirt and grease to keeping surfaces shiny and clean, it requires the right tools and skillset. Round Silicon Carbide Brush (RSCB), a product of the leading manufacturing company, is an innovative solution that makes cleaning efficient, effective, and easy.The RSCB is a circular brush that features silicon carbide bristles. Silicon carbide is a durable and abrasive mineral that can withstand high temperatures and pressure, making it a superior material for cleaning and polishing. The bristles are firmly anchored to the brush's base, providing a robust and long-lasting cleaning tool.The RSCB can clean a variety of surfaces, including concrete, stones, and metals. It is especially useful for removing rust, corrosion, and paint from surfaces. The brush's abrasive bristles are also great for preparing surfaces for painting and coating applications.The RSCB is available in various sizes and shapes, allowing it to be used with different tools and equipment. It can be attached to hand-held machines, angle grinders, and other power tools, making it a versatile cleaning solution for different types of industries.Benefits of using the RSCBHeat Resistant: Silicon carbide can withstand high temperatures, making it ideal for use in high-heat applications. The RSCB does not melt or deform under extreme heat, ensuring consistent performance.Abrasive: The RSCB's abrasive bristles are effective in removing stubborn dirt, grime, corrosion, and paint from surfaces quickly. This reduces the time and effort required to clean surfaces.Durable: The silicon carbide bristles are durable and long-lasting, providing consistent performance for extended periods.Versatile: The RSCB can be used with different tools and machines, making it a versatile cleaning solution that can adapt to different job requirements.Cost-effective: The RSCB's long-lasting and durable bristles reduce the need for frequent replacements, saving costs in the long run.The company behind the RSCBThe RSCB is manufactured by an international company that specializes in producing industrial cleaning and maintenance solutions. The company has been in the business for several decades and has built a reputation for providing high-quality and innovative products to its customers worldwide.The company has a research and development team that continually innovates and improves its products to meet the evolving needs of customers. It also ensures that its products are manufactured using high-quality materials and conform to international standards.The company has a robust distribution network that caters to customers worldwide. Its products are available in different countries, and it has established relationships with distributors and partners to ensure customer satisfaction.ConclusionCleaning and maintaining industrial equipment require the right tools and equipment. The RSCB, with its silicon carbide bristles, is a durable, efficient, and effective cleaning solution for different types of surfaces. Its heat-resistant and abrasive properties make it ideal for use in different industries, and its versatility allows it to be used with different machines and equipment. The company behind the RSCB is committed to providing high-quality and innovative products to its customers. With the RSCB, cleaning and maintaining industrial equipment have never been easier.

Top Tips for Using Brown Buff Abrasives in Your Projects

Los Angeles, CA - In a recent update from a leading manufacturer of industrial abrasives, the company released its latest product that boasts of superior quality and exceptional performance. The Brown Buff Abrasive, now available in the market, is a game-changer, according to the company. The company, whose name cannot be mentioned due to confidentiality reasons, claims that the latest abrasive is an excellent solution for industrial and domestic applications that require precision grinding, polishing, and finishing.Since its founding, the company has been at the forefront of designing and producing industrial abrasives that have helped redefine the industry. The company specializes in manufacturing a wide range of abrasives, including grinding wheels, sandpaper, polishing pads, and discs, among others. All these products are designed to meet the needs of a wide range of applications, from simple DIY projects to heavy-duty industrial processes.The Brown Buff Abrasive is the latest addition to the company's product line, and it comes with a host of features that elevate it above the rest. According to the company, the Brown Buff Abrasive is made from high-quality materials that have been carefully selected and tested to ensure optimal performance. The abrasive is designed to deliver fast and consistent results, making it ideal for precision grinding, polishing, and finishing of a broad range of surfaces. The abrasive is highly versatile and can be used on metals, plastics, and even wood.One of the unique features of the Brown Buff Abrasive is its ability to deliver a high luster finish on metals and other surfaces. The abrasive generates a smooth and uniform finish that is free from scratches and other surface defects. According to the company, the Brown Buff Abrasive is perfect for use on stainless steel, aluminum, and other metals, where a mirror-like finish is required. The abrasive's performance is further enhanced by its ability to generate less heat during operation, ensuring that the workpiece remains cool, and there is no risk of distortion or warping.The company also notes that the Brown Buff Abrasive is highly durable and can withstand heavy use without losing its cutting power or wearing out prematurely. The abrasive's long lifespan makes it an excellent investment for businesses that rely on abrasives for their operations. The abrasive is also easy to use and requires minimal maintenance, making it a popular choice for businesses that want to minimize downtime and increase productivity.The Brown Buff Abrasive is available in a variety of formats, including discs, wheels, and pads. The company offers a range of sizes and grits to suit different applications and user needs. The company's sales team is available to guide customers on the best abrasive for their specific application and to answer any questions they may have about the product.In conclusion, the Brown Buff Abrasive is a significant improvement in the industrial abrasives sector. The product has already received positive reviews from early adopters, who have praised its superior quality, performance, and versatility. The company's commitment to developing high-quality abrasives is evident in the Brown Buff Abrasive's design and manufacturing process. With this latest product, the company has once again proven that it is a leader in the industrial abrasives sector and is committed to meeting the evolving needs of its customers.

Discover the Superior Performance of Resin Bond Diamond Grinding Disc

Title: Innovative Whole Resin Bond Diamond Grinding Disc for Enhanced Grinding EfficiencyIntroduction:In the ever-evolving manufacturing industry, the need for high-quality grinding tools is paramount. Offering a cutting-edge solution, a renowned company [brand name omitted] has introduced an extraordinary Whole Resin Bond Diamond Grinding Disc. This state-of-the-art diamond disc combines advanced technology with industrial expertise to redefine grinding efficiency and productivity. With its unique design and promising features, this grinding disc is set to revolutionize various grinding applications.1. Enhanced Grinding Performance:The Whole Resin Bond Diamond Grinding Disc provides a significant boost to grinding performance by delivering superior polishing results. Its advanced resin bond technology ensures efficient material removal, reducing the time and effort required for grinding tasks. With its ability to grind a wide variety of materials, such as concrete, granite, and marble, this diamond disc offers a versatile solution for different industries, including construction, fabrication, and stone processing.2. Exceptional Durability:Durability is a key factor in any grinding tool, and the Whole Resin Bond Diamond Grinding Disc excels in this aspect. Crafted with meticulously selected industrial-grade diamonds and a high-quality resin bond, the disc exhibits exceptional wear resistance. This ensures its longevity even in demanding grinding conditions, thereby reducing downtime and replacement costs. The disc's enhanced durability combined with its high grinding efficiency makes it a cost-effective choice for businesses seeking long-term productivity.3. Efficient Heat Dissipation:Overheating during grinding can negatively impact the tool's performance and compromise the final finish. The Whole Resin Bond Diamond Grinding Disc addresses this concern by incorporating efficient heat dissipation properties. The unique resin bond formula used in manufacturing the disc allows for rapid heat dispersion, minimizing the chances of material damage and ensuring smooth operation even during prolonged usage. This innovative feature enhances the disc's overall performance and extends its service life.4. Precise and Consistent Grinding:The Whole Resin Bond Diamond Grinding Disc is engineered to provide precise and consistent grinding results with minimal variation. Its accurately placed diamond particles, thanks to advanced manufacturing techniques, guarantee uniform grinding across the entire surface. This ensures a smooth finish and avoids unevenness, enhancing the overall quality of the grinding process. The disc's exceptional precision makes it suitable for applications where precise material removal and surface refinement are critical.5. Ease of Use:In addition to its impressive grinding capabilities, the Whole Resin Bond Diamond Grinding Disc offers incredible ease of use. Its user-friendly design allows for effortless attachment to most grinding machines, enhancing compatibility and convenience for operators. The disc's optimized weight distribution ensures better balance and reduced vibrations during operation, leading to improved operator comfort and increased productivity. These features make the disc accessible to both experienced professionals and operators new to the grinding industry.Conclusion:The introduction of the Whole Resin Bond Diamond Grinding Disc by [brand name omitted] presents a remarkable advancement in grinding technology. Its cutting-edge features, including enhanced grinding performance, exceptional durability, efficient heat dissipation, precise grinding, and user-friendly design, make it a game-changer in the industry. By combining innovative engineering with renowned expertise, [brand name omitted] continues to provide superior grinding tools that pave the way for improved productivity and efficiency in various manufacturing sectors.

Effective 4 Inch Resin Chamfering Wheel for Precise Surface Finishing

A new product has been recently released by a manufacturing company known for their expertise in producing high-quality products for various industries. This new product, a 4 inch resin chamfering wheel, has been designed to provide efficient and effective grinding and polishing solutions to consumers in need of a superior product.The company behind this innovation has been in existence for decades, and its team of experts comprises of highly skilled technical personnel with years of experience in the manufacturing industry. They are dedicated to producing products that meet the highest standards of quality, efficiency, and safety.The 4 inch resin chamfering wheel, designed by this manufacturing company comes with numerous advantages that are sure to make it a favorite among customers seeking top-quality products.Firstly, this new product boasts of excellent grinding and polishing capabilities that are unmatched by any other existing products in the market. Its advanced resin composition allows for a remarkably smooth and consistent grinding surface, making it highly efficient in the performance of chamfering or beveling processes. This feature, coupled with its added thickness, makes it one of the best products of its kind on the market.Furthermore, this chamfering wheel is durable and long-lasting. The resin material, combined with the meticulous manufacturing process and quality assurance protocols employed by the manufacturing company, ensures that this product is long-lasting and can withstand the rigors of heavy-duty use.Another impressive aspect of this product is its ease of use. It is perfect for those who are inexperienced in using grinding wheels and polishing surfaces, offering a smooth and consistent process that delivers remarkable results in no time. Additionally, it is compatible with various polishing machines on the market, making it highly versatile.The 4 inch resin chamfering wheel is available in different grit levels, ranging from 60 to 600. This variety allows customers to choose the most appropriate grit level for their specific requirement, ensuring that they get the desired results.Many customers have already expressed their satisfaction with this new product, praising its high-quality, performance, and durability. One satisfied customer, who is a professional decorator, shared her positive experience, stating that “this product is worth every penny, and it has exceeded my expectations”.The manufacturing company behind this new product has always been committed to providing customers with high-quality products that meet their specific needs. Their dedication and hard work have earned them a reputation as one of the best manufacturing companies on the market.Furthermore, the company operates under strict quality control measures, ensuring that their products are always of the highest standards. They also provide exceptional after-sales support and customer services, which have kept them on top of the industry for so long.In conclusion, the 4 inch resin chamfering wheel is set to disrupt and revolutionize the market with its unrivaled quality, performance, and efficiency. It is a product that meets the demands of professionals and enthusiasts alike, and is available at an affordable price. Customers can order it online or visit their local store to experience a game-changing solution that guarantees excellent results.

Enhancing Productivity with the Revolutionary Compound Abrasive in Frankfurt

Frankfurt Compound Abrasive Has Revolutionized the Polishing IndustryFrankfurt Compound Abrasive is an innovative product that has taken the polishing industry by storm. This groundbreaking compound has quickly become the go-to choice for professionals and DIY enthusiasts alike, thanks to its exceptional performance and ease of use.Developed by a renowned company in the field of abrasives, {Company Name}, this compound has been formulated to deliver superior results on various surfaces, including marble, granite, and concrete. Its unique composition consists of high-quality abrasive particles embedded in a resin matrix, ensuring optimal polishing performance with minimal effort.One of the key advantages of Frankfurt Compound Abrasive is its versatility. It can be used with different polishing machines, such as hand-held polishers or floor machines, making it suitable for a wide range of applications. Whether you need to polish small, intricate surfaces or large floor areas, this compound provides consistent and reliable results.Furthermore, Frankfurt Compound Abrasive is designed to be long-lasting, ensuring that you get the most out of each application. Its high-quality composition resists wear and tear, allowing for extended use without compromising on performance. This not only saves time and money but also ensures a consistent finish throughout the entire polishing process.In addition to its durability, Frankfurt Compound Abrasive is known for its exceptional polishing capabilities. The abrasive particles in the compound effectively remove scratches, stains, and blemishes on the surface, revealing a smooth and glossy finish. This remarkable polishing action is achieved without leaving any swirl marks or uneven spots, resulting in a flawless appearance.Another noteworthy feature of Frankfurt Compound Abrasive is its user-friendly nature. The compound is easy to apply and does not require specialized skills or training. Simply attach the appropriate polishing pad to your machine, apply a small amount of the compound, and start polishing. Its consistent texture and ease of spread ensure a uniform application, while its quick-drying formula allows for efficient use of time.Furthermore, Frankfurt Compound Abrasive is formulated to minimize dust and residue during the polishing process. This not only provides a cleaner working environment but also reduces the need for extensive cleanup afterward. The compound's low dust generation also contributes to a healthier working environment for operators, reducing respiratory risks commonly associated with abrasive materials.Beyond its impressive performance, Frankfurt Compound Abrasive is also environmentally friendly. The compound is free from harmful chemicals and toxins, ensuring a safe and sustainable polishing solution. Its water-based formula eliminates the need for harsh solvents and reduces potential harm to both users and the environment.With its numerous advantages, Frankfurt Compound Abrasive has revolutionized the polishing industry. Professionals now rely on this innovative product to achieve exceptional results efficiently, while DIY enthusiasts appreciate its ease of use and consistent performance. As the go-to choice for polishing various surfaces, this compound has set a new standard for quality and reliability in the industry.In conclusion, Frankfurt Compound Abrasive, developed by {Company Name}, has proven to be a game-changer in the polishing industry. This versatile, long-lasting, and high-performing compound offers remarkable polishing capabilities, ease of use, and eco-friendliness. With its revolutionary properties, Frankfurt Compound Abrasive has cemented its position as the preferred choice for polishing professionals and enthusiasts alike.

Exploring the Latest Innovations in Diamond Fickert and Diamond Tools from China

Title: Chinese Diamond Fickert and Diamond Tools Revolutionizing the Stone Processing IndustryIntroduction:The stone processing industry has experienced a significant revolution with the introduction of China's superior quality Diamond Fickert and Diamond Tools. These advanced stone cutting and polishing tools have not only improved the efficiency and precision of stone processing but also revolutionized the overall quality of finished products. This news article explores the impact of China's Diamond Fickert and Diamond Tools, their manufacturing process, and the company behind their production.China's Diamond Fickert and Diamond Tools:China's Diamond Fickert and Diamond Tools have become highly sought-after in the stone processing industry due to their exceptional quality, durability, and cost-effectiveness. These tools are primarily used for grinding, shaping, and polishing granite, marble, and other natural stones, transforming them into exquisite countertops, floor tiles, and other architectural elements.Unlike traditional stone processing tools, Diamond Fickert and Diamond Tools incorporate a unique diamond-studded design. These diamond segments are firmly embedded into the base of the tools, allowing for maximum durability, precision, and longevity. The innovative use of diamond material ensures efficient and consistent cutting, resulting in a smoother finish and reduced processing time.Manufacturing Process:The production of China's Diamond Fickert and Diamond Tools involves several intricate steps to ensure the highest quality and performance. The manufacturing process begins with the selection of top-quality diamond grits and metal powders, sourced from trusted suppliers. These materials are then carefully mixed and compressed, using advanced technologies to create the diamond segments.The diamond segments are meticulously bonded to the base, usually made of high-quality steel, using a combination of heat and pressure. Additionally, advanced machinery is employed to shape and mold the tools into their desired forms. Finally, the tools undergo rigorous quality checks before being made available in the market.Company Introduction: One of the leading manufacturers of China's Diamond Fickert and Diamond Tools is {Insert Company Name}. Established in {Year}, {Company Name} has gained a solid reputation for its commitment to producing high-quality stone processing tools. The company utilizes state-of-the-art machinery, cutting-edge technologies, and a team of skilled professionals to ensure the production of superior tools.{Company Name} focuses on extensive research and development, continuously improving its product range to meet the evolving demands of the stone processing industry. Moreover, the company adheres to stringent quality control measures, strictly monitoring every phase of the manufacturing process. This dedication to quality and customer satisfaction has established {Company Name} as a trusted supplier in both domestic and international markets.Conclusion:China's Diamond Fickert and Diamond Tools have undoubtedly revolutionized the stone processing industry, providing an unparalleled level of precision, efficiency, and quality. With their exceptional durability and cost-effectiveness, they have become the tools of choice for stone processors worldwide. Through innovation and a commitment to excellence, {Company Name} has played a significant role in advancing this field, showcasing the prowess of China's diamond tool manufacturing industry. As the industry continues to evolve, China's Diamond Fickert and Diamond Tools are set to shape the future of stone processing, enabling the creation of exquisite architectural elements that will captivate the world.